Welcome to

Dean Bennett Supply

FOR OVER 60 YEARS HELPING PEOPLE SAVE MONEY

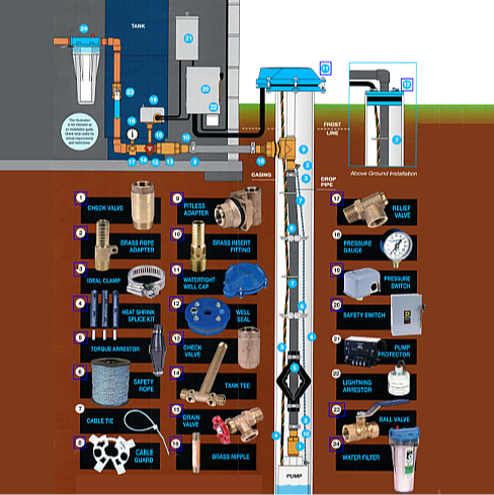

Whether your pumping needs are for household use or for livestock watering, our knowledgeable sales people will guide you to the correct products. Our large Denver inventory of well supplies will make fast delivery of your order easy.

$2500 Net Orders are Full Freight Allowed

Pipe and Rod Not Included

Quick Links to Popular Product Categories:

Dean Bennett Supply Company has been a stocking distributor of pumps and well supplies since 1965.

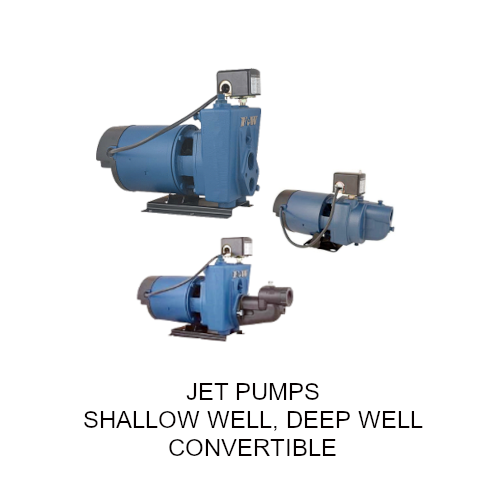

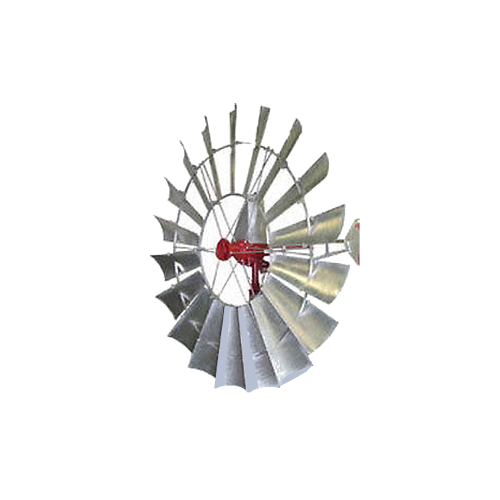

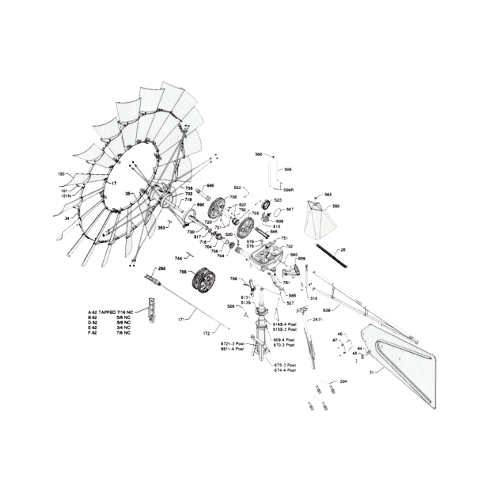

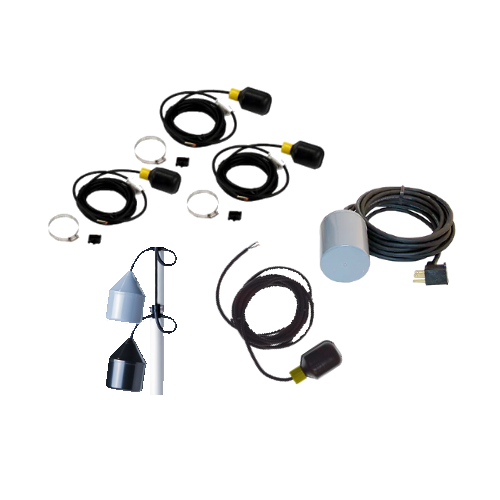

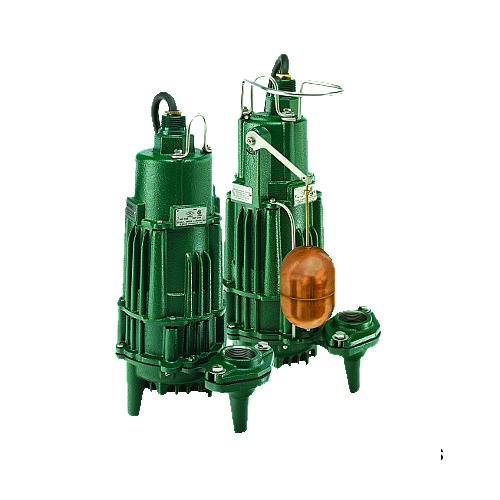

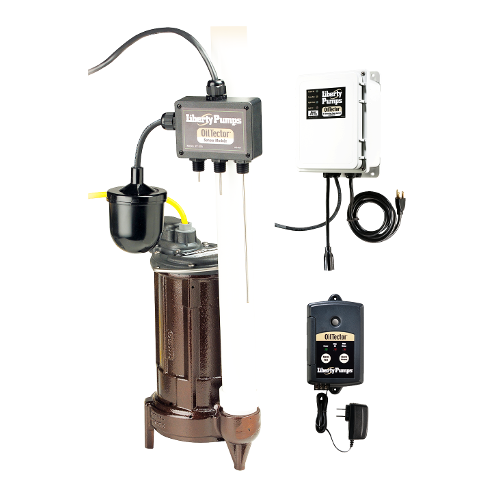

Submersible Water Well Pumps, Sump Pump and Sewage Pumps, Water Well Accessories, Windmills & Hand Pumps, and Environmental Ground Water Monitoring Supplies. DEAN BENNETT SUPPLY at 1-866-746-1213 is your supplier for Wind Engine 702 windmills, Zoeller sump and sewage pumps Flint & Walling submersible and above ground water well pumps and water well accessories such as tanks, valves, etc. Since 1965 Dean Bennett Supply has served the needs for water pumping systems for livestock, homes, and businesses. We welcome the DO-IT-YOURSELF Installer.

Your quality concerns will disappear when you can select brand name merchandise from well known manufacturers like Flint & Walling pumps, Wind Engine 702 windmills, and Zoeller sump and sewage pumps. We serve the rancher, home owner, and Do-It-Yourself installer in addition to the professional well driller / pump man - - So don't hesitate to call us for help on the products we sell you.